The Making of a Rotary Float

Last year the Rotary wheel float we have borrowed for years from the Marysville Club, was unavailable for the Frontier Days Parade and the Duck Dash, since the San Juan Island Club beat us to the ask. Our response--We need a float of our own!

Carla Gastineau, our Club Administration Director and the manager of the Stillaguamish Athletic Club, asked Chris Whiteman, a SAC member and the Career and Technical Educator at Arlington High School, if it is something his students could do as a learning project. Chris jumped at the chance.

Chris brought 2 of the 7 members of his metal fabrication class who worked on the project to update us at our May 31 meeting.

Chris Whiteman, Right, with Students Tucker and Jayden on the Left

The project was to fabricate a trailer with a collapsible 7 foot high Rotary wheel. It took two weeks to fabricate the frame for the trailer. It will have a lower tongue frame, leaf spring mounts, with diamond plate decking. Tucker, a junior, talked about the cutting and welding involved.

To build the collapsible wheel a Plasma C & C cutting machine was used. The wheel is in sections. Jayden, who is a sophomore, indicated it was very time consuming. It is made out of 1/8th inch steel plate. Here is a photo of one of the other students with section in hand:

.jpg)

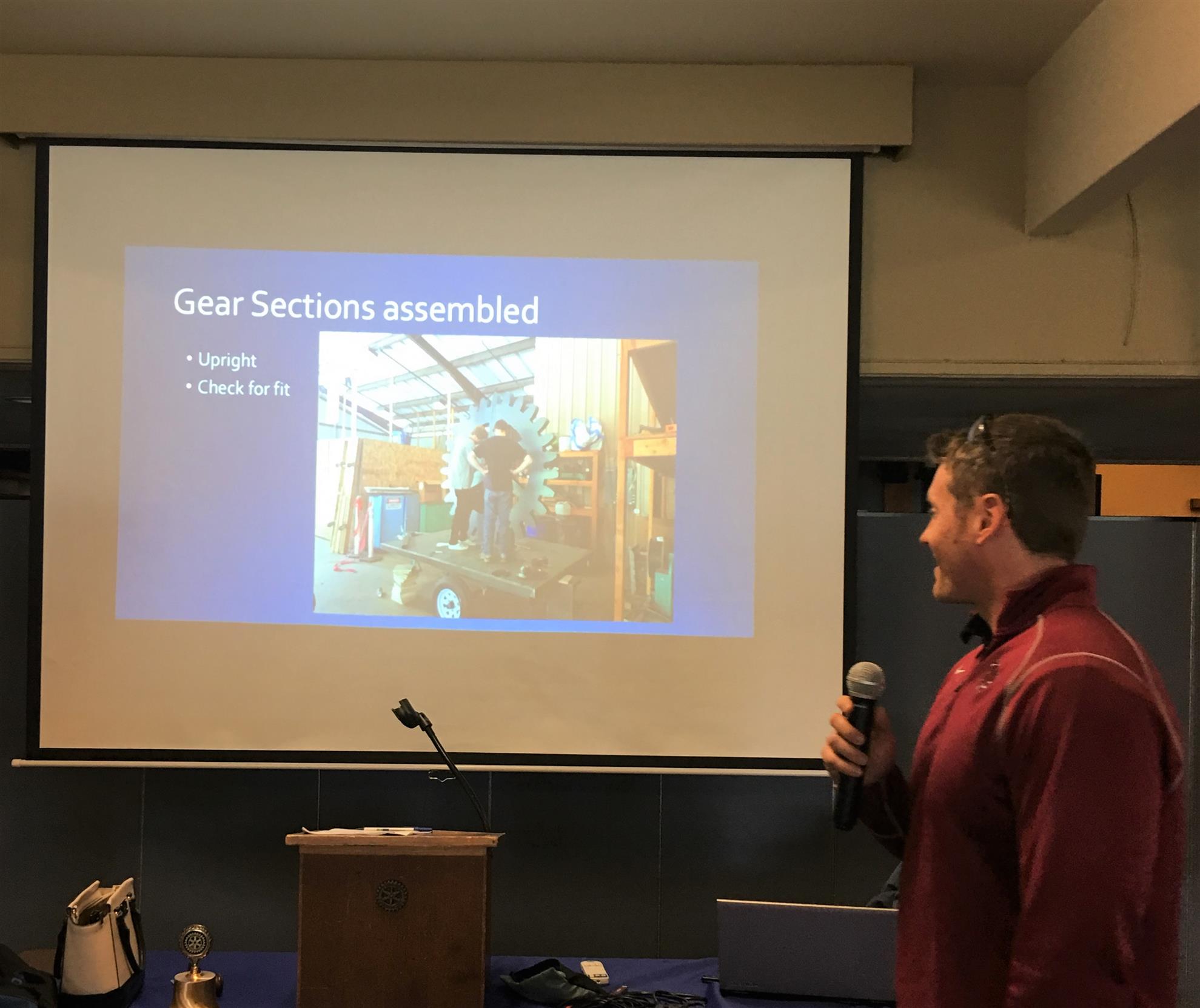

Chris pointed out that assembly was not like putting together a piece of furniture at Ikea. There is no "put tab A into slot B". He credited Tanner, not pictured, who he has in 3 classes for spending the time to make sure everything fit together.

The wheel is bolted to the trailer bed and it will fold down flat. When up right, it will be about 9 feet tall, including the trailer. The trailer will have side rails for hanging banners.

Chris with Slide Showing Attaching Wheel to the Trailer

The trailer and float is being transported to be painted by our own Wally Thomas and John Peeters' company, Artisan. Although graduation for seniors is June 8, the last day of school is June 18, giving the underclassmen in the class time to reassemble the painted parts.

Chris took the opportunity, in answer to a question, to tout the trade event recently held in the bus loading area of Arlington High School. 31 different businesses put up displays and brought equipment to highlight the technical trades available to graduating students. 30 different students obtained seasonal jobs and internships as a result of the event.

To learn more about the trade event and see the companies represented, click HERE.